University of North Dakota, New Steam Plant

The Customer Challenge

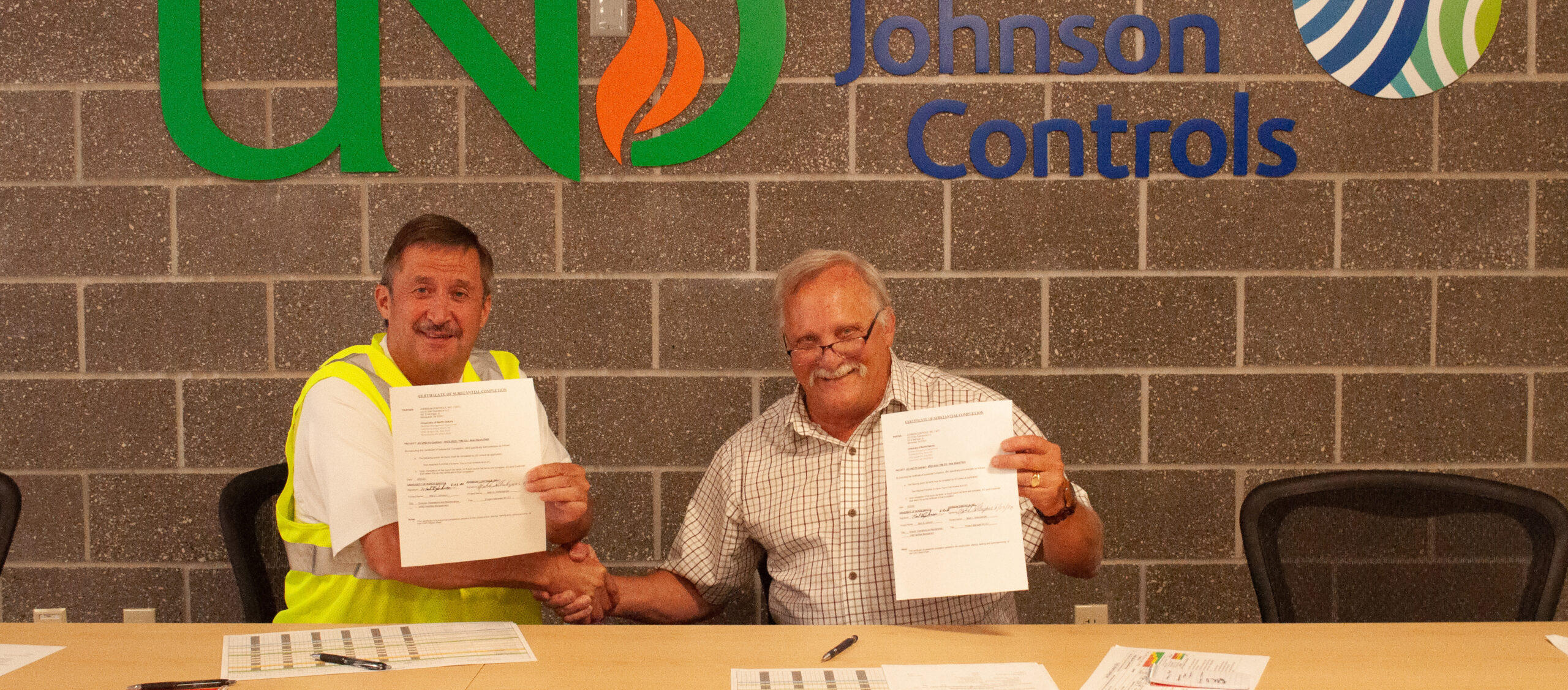

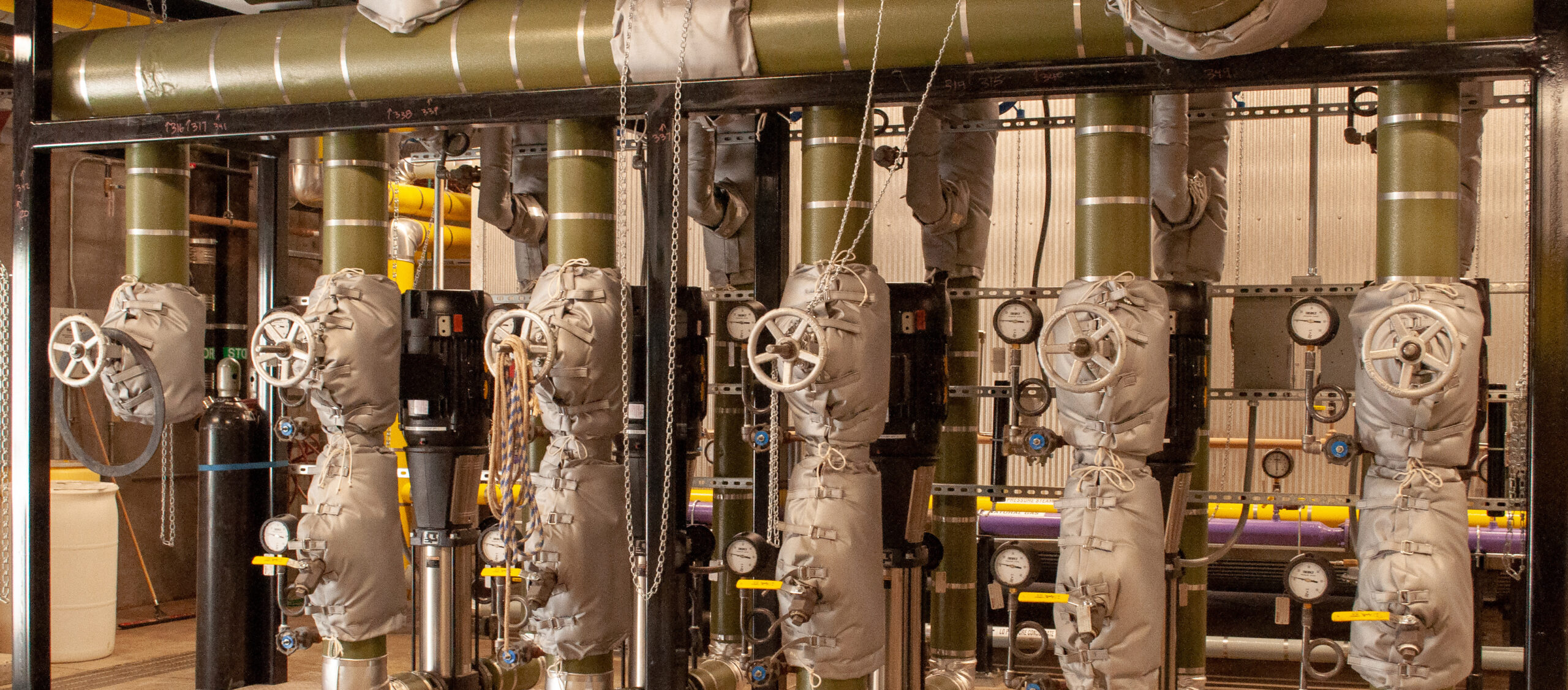

Bitterly cold, snowy and windy. That’s winter in Grand Forks, 75 miles north of Fargo in North Dakota. With such extreme conditions, it’s critical to build or at least dry-in a structure before temperatures drop. Our client, Johnson Controls Inc. (JCI), needed a partner that could ensure flawless on-time delivery for a new steam plant project at the University of North Dakota. The plant needed to be fully erected and enclosed in 6½ months during spring and summer. Additionally, five massive 60,000 lb/hr steam boilers and all supporting equipment had to be in place during the same timeframe. Temporary heating for the new plant was also needed to allow interior work to continue throughout winter. For boiler installation – including testing, startup and commissioning – another 6½ months was allocated. Ultimately, the new plant would supply steam for comfort heating, domestic water heating and sterilization processes to campus buildings, including an onsite hospital. With year-round demand for steam, there could be no interruption to steam supply when transitioning from the existing plant to the new one.

The Sylvan Solution

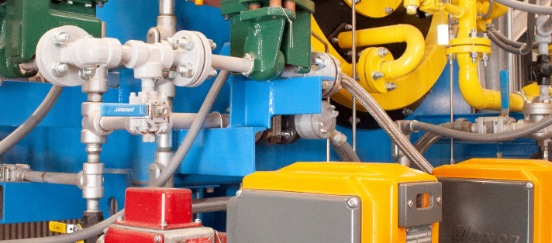

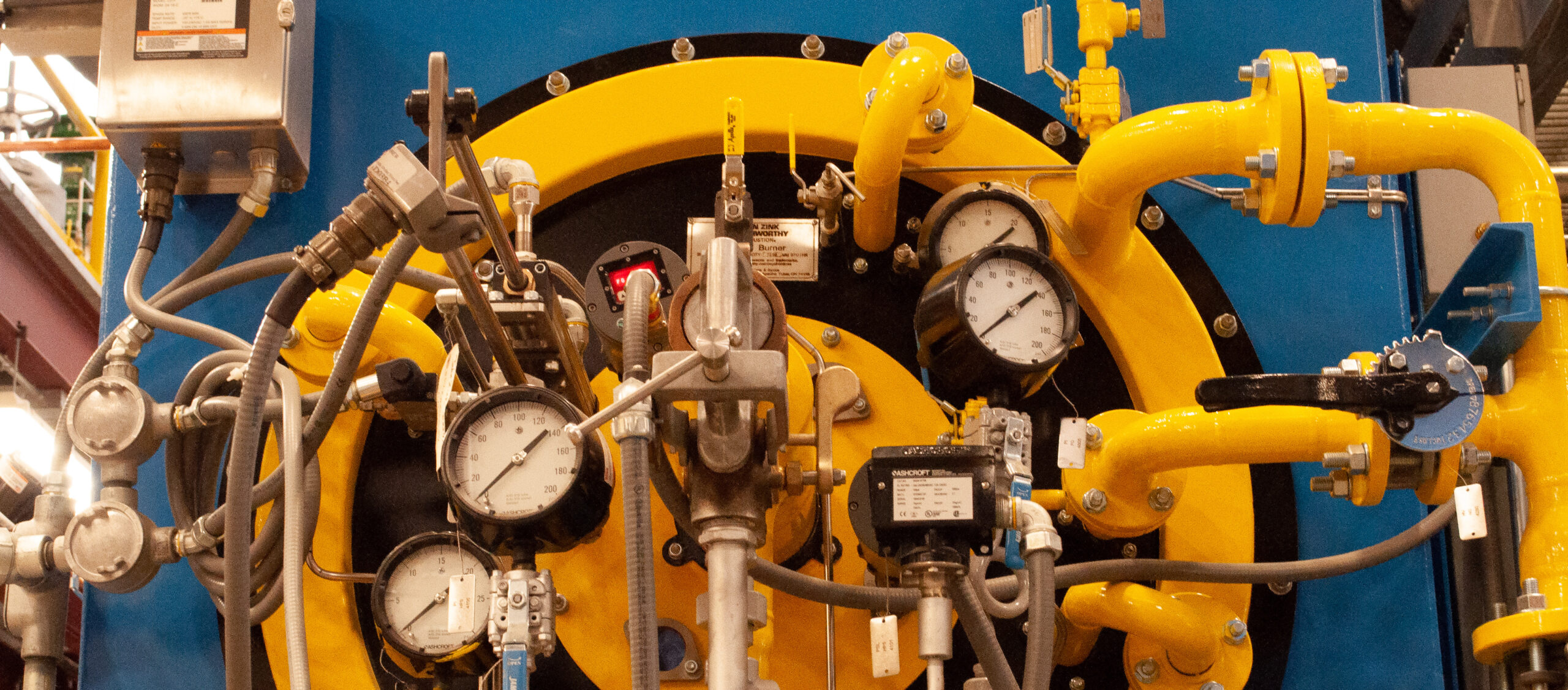

Sylvan managed all design work, equipment setting, pipe fabrication, installation and startup services. We contracted with a fabrication shop in Fargo to utilize local labor and minimize shipping costs. Similarly, we partnered with local subcontractors for insulation, wiring and sheet metal. We developed fabrication drawings and managed subcontractors to fabricate piping assemblies as design continued. Coordinating with the general contractor erecting the new plant, we oversaw crane load-in of boilers, support equipment and prefabricated piping assemblies into the building prior to roof installation. Utilizing the new natural gas service to the plant, we installed a temporary heating system to maintain a comfortable indoor climate, even when outdoor temperatures plummeted to -23F. To expedite startup, we developed a piping system in which steam from the existing plant was routed to the new plant to allow testing of boiler support systems and equipment prior to completion of the new boiler installation. In the final phase of the project, we provided testing expertise and support to ensure a smooth startup.

The Result

All phases of the project were executed on-time, with final completion a week ahead of schedule. The project was completed without any interruption of vital steam supply to campus building facilities. The new modern steam plant provides the university with a much-needed and reliable source of steam. Demolition of the old steam plant (circa 1940s) began immediately following completion of the new plant. Meeting the project schedule allowed the existing plant demolition to be complete before winter’s arrival.